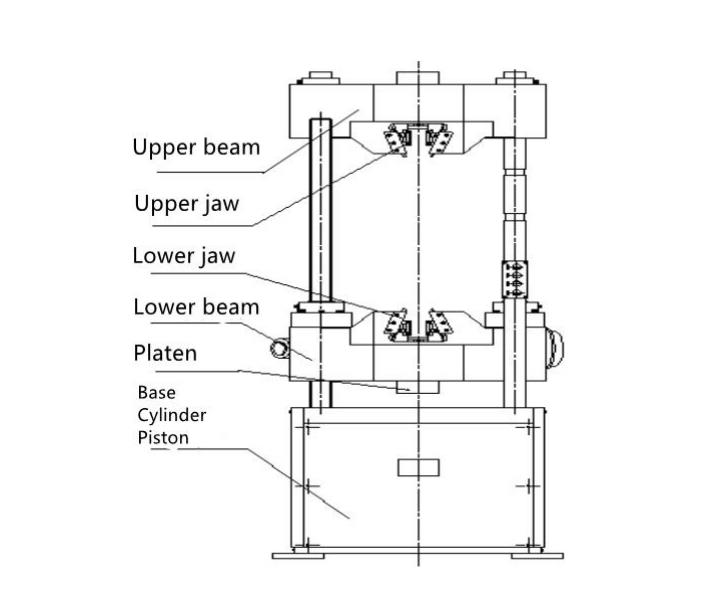

WAW-1500Dmicrocomputercontrolledelectro-hydraulicservouniversaltestingmachinehostadoptsacylinder-mountedhost,whichismainlyusedformetalandnon-metaltensile,compression,bendingandsheartests.Itissuitableformetallurgy,constru

WAW-1500D microcomputer controlled electro-hydraulic servo universal testing

machine host adopts a cylinder-mounted host, which is mainly used for metal and

non-metal tensile, compression, bending and shear tests. It is suitable for metallurgy, construction, light industry, aviation, aerospace, materials, colleges and universities, scientific research institutions and other fields. The test operation and data processing meet

the requirements of GB228-2002 "Room Temperature Material Metal Tensile Test Method".

Main performance and technical indicators

(1)Maximum test force: 1500kN;

(2)Test force measurement range:40KN-1500kN;

(3)Test force indication accuracy: ±1%;

(4)Displacement measurement resolution:0.005mm;

(5)Deformation measurement: standard configuration gauge length 50mm, maximum

deformation 10mm. (6)Deformation measurement accuracy: ±0.5%

( 7 ) Constant force, constant deformation, constant displacement control range:

0.4%~100%FS

(8)Constant force, constant deformation, constant displacement control accuracy:

When the setting value is less than 10% FS, within ±1.0% of the setting value

When the set value ≥ 10% FS, within ±0.5% of the set value

(9)Deformation rate control accuracy:

When the rate is less than 0.05% FS, it is within ±2.0% of the set value

When the rate is ≥0.05%FS, it is within ±0.5% of the set value

(10)Maximum moving speed of piston:60mm/min;

(11)Maximum tensile test space:1050mm(Including piston stroke)

(12)Maximum compression test space:1000mm(Including piston stroke)

(13)Flat specimen clamping thickness:0-70mm

(14)Clamping diameter of round specimen:φ10-φ75mm

(15)Pressure plate size:∅ 240 mm

(16)Bending test roll spacing: 450 mm

(17)Roll width:140mm

(18)Pivot diameter: 50mm

(19)Piston stroke:250mm;

(20)Clamping method: hydraulic clamping

( 21 ) Amplifier: Program-controlled amplifier inserted in the PC, automatic zero

adjustment and calibration

(22)Dimensions:Host:1200×800×3200mm

Oil source:1200×700×930mm

(23)Total Weight:7500 kg

System Configuration List

(1)The main engine of the testing machine:The main engine with the oil cylinder

under-mounted

(2)Oil source for servo control:Platform type

(2.1)Electro-hydraulic servo valve:Dedicated Servo Valve

(2.2)Imported high pressure gear pump:Imported Mazuki

(3)STC300 Dual channel programmable amplifier:Resolution 1/300000

(4)High-precision load sensor:Ningbo Zhenhai

(5)Extensometer YYU50-20: Beijing Iron and Steel Research Institute (optional)

(6)Pull-wire displacement measurement system

(7)A full set of attachments include: tension, compression, and bending attachments

(8)EVOTEST Dedicated control software

(9)Lenovo Commercial Brand Machine

(10)HP A4 inkjet printer

Chengyu Testing Equipment

Scan QR for more